What the Date Trade Can Teach Us About Quality, Profit—and Pecans

Applying the 1-10-100 Rule to Premium Food Imports in India

This story is a fictional illustration inspired by real experiences. All characters represent composite insights.

Kavir had built a strong business in Mumbai over the past 12 years.

He was no stranger to dried fruit imports—his Medjool dates came from the best sources in Jordan and Tunisia. His pistachios were the envy of local retailers. His almonds flew off shelves each festival season. But pecans? They remained a frustrating mystery.

Pecans were new to Indian consumers, yes. But so were cranberries and avocados only a few years ago.

Loads moved slowly. Too slowly. With each shipment, he hoped the numbers would improve. He began to question whether pecans were worth the hassle.

Until he looked back at his experience with Medjool dates.

The 1-10-100 Rule—and the Lesson of Dates

There was a time when Kavir had to learn how to make money on dates, too.

He remembered a specific summer shipment years ago. The price was attractive. The packaging looked fine. All the boxes for customs compliance were done. But the results? Sticky messes, bitter taste, and complaints - and even worse, slow or no payments.

He had to offer discounts. Several clients didn’t reorder. He lost weeks of trust.

That’s when he learned the 1-10-100 Rule.

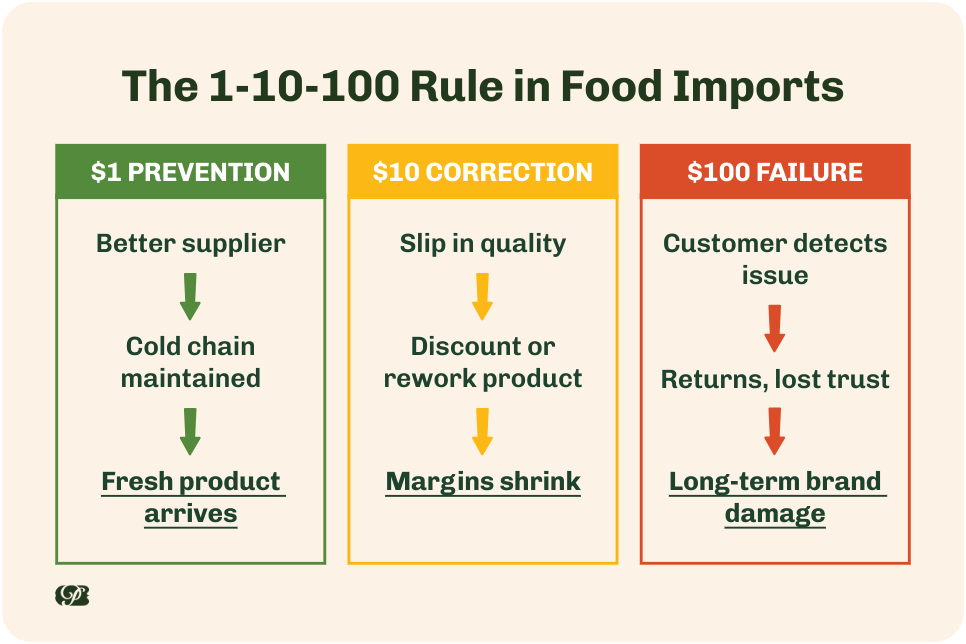

The 1‑10‑100 Rule—Why it Matters in Food Imports

As explained by management expert Michael Canic:

"You can spend $1 to prevent a problem, $10 to correct it, or $100 if the customer finds it."

In other words:

Spend $1 upfront to ensure quality

Or spend $10 fixing issues

Or lose $100 in reputation, lost sales, and long-term impact

The "1‑10‑100 Rule" is a well‑established global business principle in quality management. As Canic explains:

"The cost of prevention includes what it takes to get things right on the front end… The cost of correction is the cost of fixing or removing defects once a problem is identified … Finally, the cost of failure is the resulting downstream cost if a problem isn’t fixed before the customer experiences it. The cost of quality is not just a financial measurement. It’s a cultural shift—one that transforms how organizations view prevention versus reaction.”

Additional experts echo this:

“Detecting quality problems early in the manufacturing process is less costly than catching a quality challenge later… Finding a mistake in product development costs less than in production; finding it in production costs the company less than once the product is out the door.” — WorkClout

In simple terms:

$1 = a small preventive step (like ensuring freshness through cold-chain handling)

$10 = a corrective action (discounting or reworking product)

$100 = a costly failure (lost trust, returns, canceled accounts)

This exponential cost model has become a benchmark for industries worldwide—from manufacturing to healthcare, from data management to finance… and of course, food.

Dates taught Kavir a valuable lesson that he needed to apply to his pecan business in order for it to grow: freshness and handling matter more than product or origin alone.

The Pecan Problem—and a Familiar Pattern

When Kavir examined his pecan imports with the same lens, the pattern was clear:

Oxidized flavor even after short storage periods

Flaky, broken pieces despite proper handling

No complaints, but also no growth

The 1-10-100 Rule had struck again. But this time, the fix wasn’t just better packaging—it required a better system.

He remembered what he had learned from his date suppliers: invest in partners who invested in quality.

So he called Prime Pecan.

How Prime Pecan Changed the Math

Kavir wasn’t looking for magic. He was looking for a profit margin.

Prime Pecan offered something different:

Lab-verified freshness

Cold-chain handling and MAP sealing

Creamy, sweet, clean flavor that held up in India heat

Fewer fragments, less waste

The category began to turn. Retailers began reordering. Chefs in Mumbai and Delhi requested the same pecans again.

What had once taken 60 days to reorder now took 30.

The pecan math had changed.

“Every rupee I tried to save up front was costing me ten—or a hundred—later. Freshness isn’t a luxury—it’s the only way the category grows.”

Dates and Pecans: The Shared Path to Profit

All dried fruits share the same rules:

Heat, humidity, and time are enemies of shelf life

Flavor stability and texture drive reorders

Proof of freshness builds downstream trust

Just as the date trade now recognizes freshness as the profit driver, Prime Pecan is helping importers apply the same mindset to pecans.

This isn’t about origin stories or romantic orchard tales.

It’s about systems that scale.

Kavir’s Rule: Spend $1 to Save $99

The 1-10-100 Rule isn’t just theory.

It’s the story of how the same importer who once doubted pecans turned the category into a margin builder—just like his Medjool dates.

Prime Pecan helps importers avoid waste, accelerate reorders, and build a pecan business that performs.

Is this your pehla kadam badlav ka — your first step toward change?

Let’s run your numbers.

Contact us to learn how to save $99 by spending $1.

FAQ: Common Questions from Global Importers

-

It's a business rule that shows the cost of quality at different stages. Spend $1 upfront for quality, or $10 to fix problems, or $100 if issues reach the customer. In food importing, this applies to shelf life, flavor degradation, and returns.

-

Both are high-value, perishable, and commonly imported into India and the Gulf. Importers familiar with dates understand the cost of freshness—and the same principles now apply to pecans.

-

Our freshness systems from orchard to port, our handling guidance and support to importers and verified freshness via lab tests ensure the product performs longer, reduces complaints, and increases reorder speed—especially in hot, humid climates like India.

-

Yes. We’ve worked in India since 2019, and our systems are optimized for Indian climate and distribution.